EOE-based easy-peel film is increasingly making its mark in the packaging industry due to its unique combination of functional and practical benefits. This type of film is designed to offer a peel force that is consistently manageable, typically ranging between 3 to 10 N/15 mm, with customization options allowing for even lower forces as required. This precise control over the peel force ensures that consumers can easily access the contents of packaged products without the hassle of excessive force or unwanted tearing, which is especially crucial in enhancing user experience and convenience.

The versatility of EOE-based easy-peel film makes it suitable for a wide range of applications. In the food packaging sector, it is commonly used for packaging ready-to-eat meals, snacks, and fresh produce. Its ability to provide a reliable peel force without compromising the integrity of the packaging is vital for maintaining food freshness and safety. The film’s compliance with food contact safety standards ensures that it can be safely used for direct food contact, meeting regulations such as GB/T 28117. This not only ensures consumer safety but also builds trust in the brand's commitment to quality and hygiene.

In addition to food packaging, EOE-based easy-peel films find applications in the pharmaceutical and healthcare industries. For medication packaging, ease of opening is a critical factor, especially for elderly patients or those with limited dexterity. The easy-peel film allows for straightforward access to tablets or capsules while providing a secure barrier to protect the contents from contamination. The film's controlled peel force is particularly advantageous for blister packs and other pharmaceutical packaging solutions where user-friendly access and product integrity are paramount.

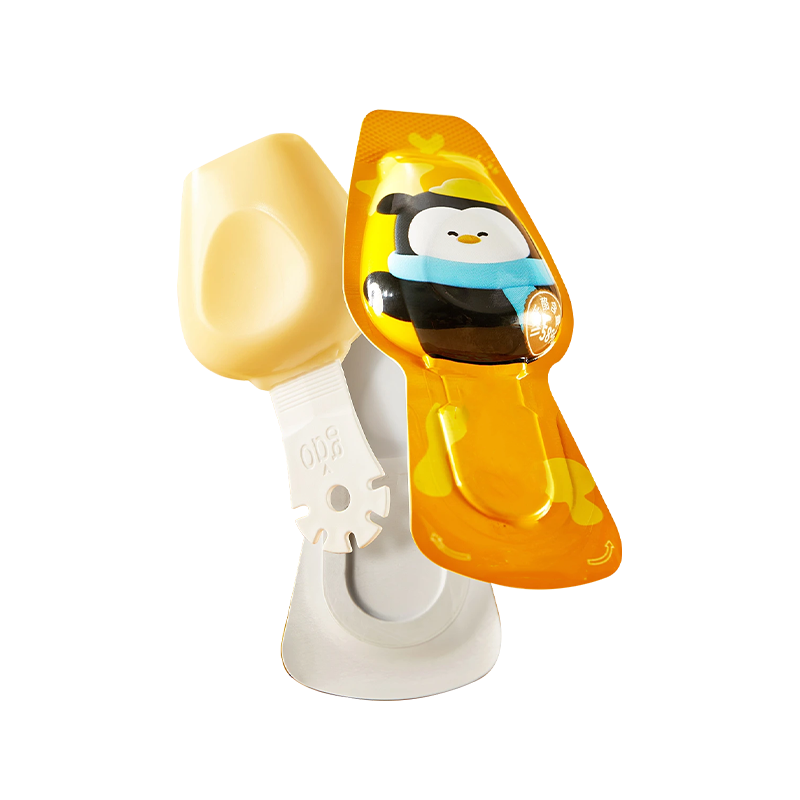

Another growing area of use is in consumer goods packaging, such as personal care products and household items. For example, products like shampoos, lotions, and cleaning agents benefit from the easy-to-open feature of the film, which enhances the overall user experience. Additionally, the film’s control over visual defects like black dot crystal points ensures a professional appearance, which is important for maintaining brand image and consumer satisfaction.

Beyond its practical applications, EOE-based easy-peel film is also gaining attention for its role in sustainable packaging solutions. As industries increasingly focus on reducing environmental impact, the ease of recycling and the film’s potential for use in eco-friendly packaging options are becoming more significant. While the environmental impact of the film is an area of ongoing development, its current features represent a step towards more user-centric and functional packaging solutions.

The typical applications of EOE-based easy-peel film in the packaging industry highlight its role in enhancing consumer convenience, maintaining product safety, and supporting various sectors, from food and pharmaceuticals to everyday consumer goods. Its combination of controlled peel force, safety compliance, and versatility underscores its growing importance in modern packaging solutions.

LANGUAGE

LANGUAGE

English

English 中文简体

中文简体